Food Processing

A grease interceptor overflow in a food processing plant can cause severe damage to your image and brand.

6 ways the FOG Monitor Smart Meter will benefit your food processing and manufacturing plant

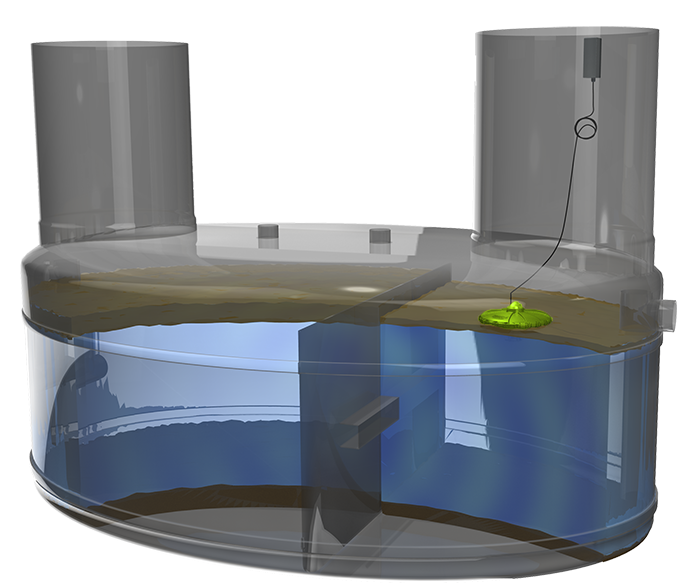

View of the FOG Monitor sitting in the interceptor

FOG Monitor is the world’s first wireless smart meter monitoring solution for grease interceptors!

Riptide Tek is introducing FOG Monitor – a new smart meter technology which will let you know when a grease interceptor is full and ready to be pumped. This technology allows liquid handling customers to automatically improve efficiency, reliability, economics, and sustainability of their FOG management process.

The FOG Monitor smart meter determines interceptor FOG and sludge levels and wirelessly send the information to a display panel showing exactly how much material is present.

The display will send out an alert when the FOG level has reached a pre-set level and that a pump-out is require. Saving the FSE pumping costs from frequent pump-outs and damages due to overflows.

- Cost reduction

- Maintain brand image

- Environmental and regulatory compliance

- Production metrics

- Avoid backups

- Sustainability

The smart-meter determines interceptor FOG and sludge levels and informs facility managers, pumpers/haulers and enforcement officials when a pump-out is needed. It records grease and sludge level data, and displays level data on a monitor panel showing exactly how much material is present in real time.